The packoff assembly isolates the sliding sleeve ports and prevents fluid migration between the tubing and casing annulus while allowing restricted flow up the production tubing from below.

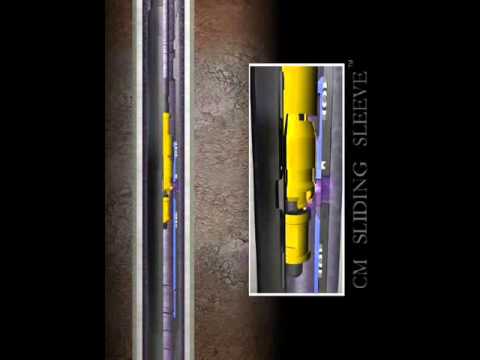

Sliding sleeve door.

The well stroker configured with 15 000 lbs force anchored in position on the 5 1 2 20 blank pipe above the sliding sleeve and powered up to stroke down and shift open the sleeve.

A sliding sleeve is a standard component for the completion of an oil or gas well.

The durasleeve sliding side door circulating and production sleeve is a full opening device that can be operated using standard slickline methods.

Open close sleeves are shifted between a full open position and a closed position.

It required two strokes to fully open the sliding sleeve door.

There are two main categories of sliding sleeves.

Optisleeve sliding sleeve weatherford s optisleeve sliding sleeve is a tubing mounted device used to regulate flow from individual producing zones or to control communication between the tubing and the annulus.

It has seal bores above and below the ports and a top no go shoulder and locking groove.

The ssd can be combined with tendeka s inflow technologies to provide inflow control when in the open position.

The sliding sleeve packoff is attached to a lock which anchors and seals in the sliding sleeve.

Tendeka s ssd enables selective flow in production and injection directions.

Once the first sleeve was opened the well was unloaded and the second sleeve opened a few days later.

The act model l sliding sleeve is a downhole tool used to establish communication when desired between the tubing and annulus.

Acting as downhole control valves sliding sleeves can also be used to circulate fluids from the annulus to the tubing above the production packer or to inject water into individual zones during waterflood operations.

Sliding side door ssd open close sliding sleeve ssd enabling selective flow for production and injection applications.

Their main uses are to shut off flow from one or more reservoir zones or to regulate pressure between zones.

The tool has one connection which minimizes potential leak paths the non elastomeric seal.